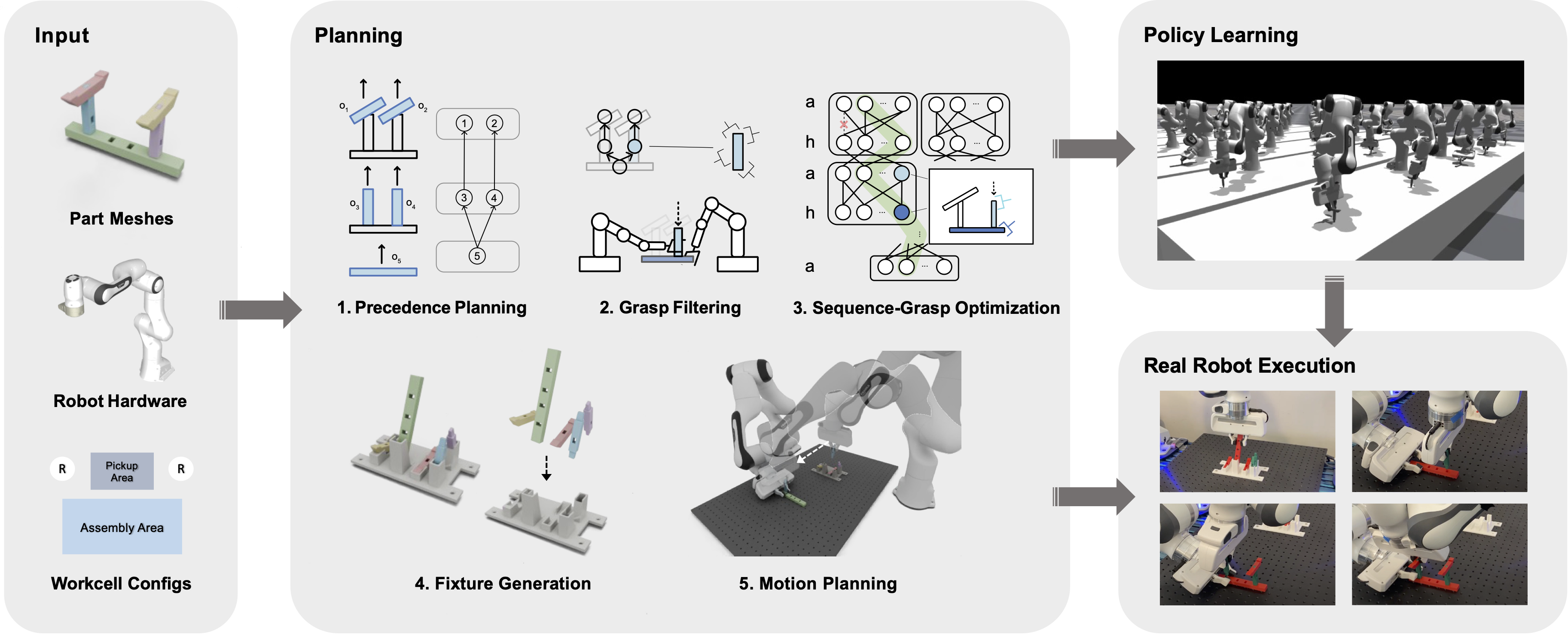

Our robotic system achieves general and precise multi-part assembly using standard dual-arm robots, seamlessly integrating holistic planning and learning-based control.

Starting from minimal inputs including just part geometries and robot configurations, our multi-stage planner autonomously generates assembly sequences, robust grasps, customized fixtures, and collision-free motion plans.

We train RL policies for precise contact-rich assembly steps with minimal yet effective designs, enabling the system to adapt to variations in object geometries and grasp poses.